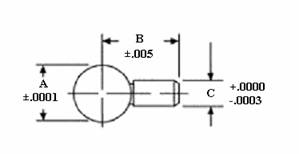

Tooling Balls (w/plain shank)

2-piece construction assembled by a proprietary welding

technique that maintains the high precision and finish of

the ball. The weld is also designed so that the ball will

break off if the subject to undue lateral force, preventing

damage to expensive equipment in the event of set up errors

and faulty readings caused by bending of shank.

Material type 440C stainless steel

Concentricity, ball to shank .0002” T.R.I. maximum

|

Part No.

|

A

|

B

|

C

|

|

40422

|

.2500

|

.5600

|

.1247

|

|

40622

|

.3750

|

.7500

|

.1872

|

|

40822

|

.5000

|

.9400

|

.2497

|

|

41022

|

.6250

|

1.060

|

.3122

|

|

41222

|

.7500

|

1.250

|

.3747

|

|

41422

|

.8750

|

1.440

|

.4372

|

|

41622

|

1.000

|

1.620

|

.4997

|

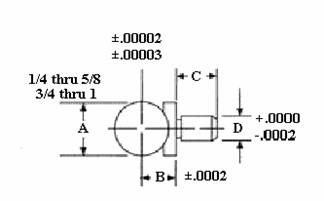

Checking Balls (w/ reference shoulder)

2-piece welded construction assembled by same welding technique

as tooling balls, but manufactured to tighter tolerance with

reference shoulder that allows for more accurate positioning,

re-positioning and/or replacements

Material type 440C stainless steel

Concentricity, ball to shank .0002” T.R.I. maximum

|

Part No.

|

A

|

B

|

C

|

D

|

|

80244

|

.1250

|

.0938

|

.3750

|

.1255

|

|

80444

|

.2500

|

.2000

|

.5600

|

.1247

|

|

80644

|

.3750

|

.3000

|

.7500

|

.1872

|

|

80844

|

.5000

|

.4000

|

.9400

|

.2497

|

|

81044

|

.6250

|

.4500

|

1.060

|

.3122

|

|

81244

|

.7500

|

.5000

|

1.250

|

.3747

|

|

81444

|

.8750

|

.6000

|

1.440

|

.4372

|

|

81644

|

1.000

|

.7000

|

1.620

|

.4997

|

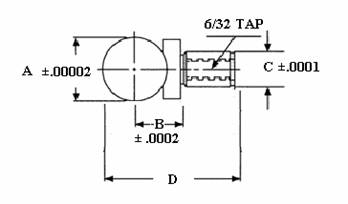

Checking Balls (w/ reference shoulder & tapped shank)

2-piece welded construction, like standard checking balls,

but with tapped shank allowing assemblies to be screwed into

position from below via a cap screw. This allows assembly

to be positioned or replaced without applying pressure to

the ball.

Material type 440C stainless steel

Concentricity, ball to shank .0002” T.R.I. maximum

|

Part No.

|

A

|

B

|

C

|

D

|

|

34822

|

.5000

|

.3125

|

.2499

|

.9600

|